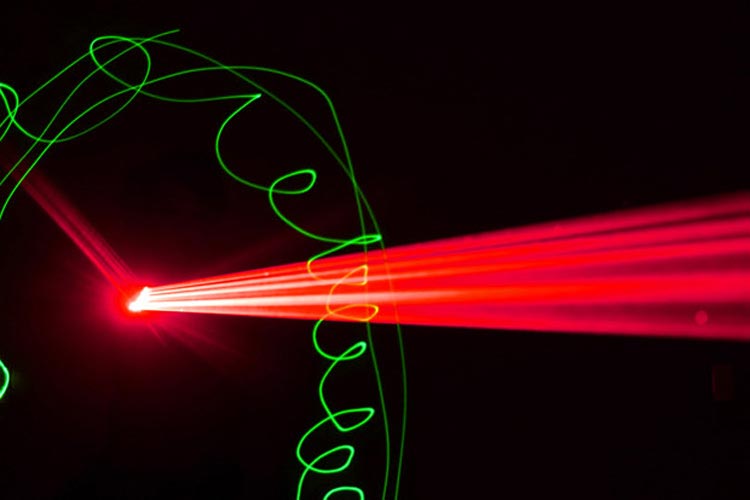

The application of the absorbent is a very important process in the plastic laser welding process. The essence of plastic laser welding is to heat the area of the plastic to be welded to melt, then cooling the natural realization of the bonding of plastic parts. Let the plastic melt the plastic parts to absorb enough laser energy. Usually the ideal absorbent is carbon black, carbon black can be infrared wavelength of the laser energy is basically all absorbed, thereby greatly improving the plastic heat absorption effect, making the heat of the material melting area faster, the better. Some other colors of dyes can also play the same effect of absorbing light waves. There are three ways to add the absorbent: one is to penetrate the absorbent directly into the material to be welded, so that the plastic parts that will penetrate the absorbent should be placed underneath, and the plastic parts without the absorbent should be placed on the surface so that the second green laser pointer is to the plastic parts to be welded to the surface of the seepage of the absorbent, so that only part of the absorbent by the plastic will become a hot zone and be melted; Third, in the two pieces of plastic parts to be sprayed at the contact or Printing on the absorbent.

From the market growth point of view, according to the type of laser, the next five years, the fastest growing market is the direct semiconductor lasers, mainly kilowatt-class high-power semiconductor lasers; the second fastest growing quantum cascade laser, this laser advantage Obviously, widely used, especially in anti-terrorism, security and other applications play an important role in the future of the global quantum cascade lasers will have a huge demand. Fiber lasers will always maintain a steady growth rate. From the application of the laser market, to remove about half of the optical communications market, the current macro-processing is the largest market, followed by micro-processing, the future with the manufacturing industry continues to high-end development, micro-processing market will have a great growing space.

The most commonly used laser welding form is called laser transmission welding, first of all two plastic parts to be welded together with pressure, and then a short wave of infrared blue laser pointer area to the site to be bonded. The laser beam passes through the upper layer of light transmission material and is then absorbed by the underlying material. The laser energy is absorbed and converted into heat energy, since the two layers of material are pressed together. The heat is transferred from the absorber layer to the light-transmissive layer so that the two layers of material are melted and bonded. At the same time due to the thermal expansion of the material itself to expand the internal pressure. Internal pressure and external pressure to ensure the two parts of the solid welding.

The beam quality of the laser output is getting better and better, and the beam quality of the fiber laser has reached a single mode of 100,000 watts. In the past year, fiber lasers, disc lasers, direct semiconductor lasers have a significant increase in brightness. The output wavelength of the laser covers a shorter band, and the short wavelength laser has been widely used. Many advanced manufacturing processes require cold processing, such as in the manufacture of smart phones, often need to use short wavelength, short pulse UV burning laser to deal with. Short wavelength lasers have been widely used in surface marking, semiconductor wafer processing, drilling, cutting and other fields. The pulse speed of the laser is getting faster and faster, and the ultrafast laser has been developed rapidly. It has been driven into industrial applications by means of simpler structure, more convenient operation, lower cost and more stable performance.

Plastic welding process commonly used is a diode laser or semiconductor laser. The beam is in the near infrared region and the wavelength of the beam is between 400 and 1,100 μm, which can be transmitted by fiber. The laser beam in this range can be absorbed by most of the plastic. Diode laser welding system is compact, and the laser can also achieve higher levels of power. The wavelength of the laser can be designed according to the special requirements. The wavelength of the semiconductor laser is generally 808 to 980 μm. Semiconductor laser investment cost is small, small size, high efficiency.

Thermoplastics contain amorphous plastic and semi-crystalline plastic. Plastic that can be laser welded is a thermoplastic. In theory, all thermoplastics can be laser welded. Plastic green astronomy laser welding technology requirements for the welding of plastic: the material in the thermal area of the requirements of the laser light absorption of good; does not belong to the thermal part of the material, the requirements of the light through the good, especially in the This is especially true for two pieces of thin plastic parts. Generally add to the heat in the plastic area of the absorbent can achieve the purpose.